top of page

Manufacturing

Wing Panels

The manufacturing process for the wing can be broken down into the structural components: leading edge, trailing edge, ribs, spar, and attachment features. The leading edge was made from rectangular balsa wood blocks that were machined by a CNC mill. The trailing edge of the wing is balsa wood, cut from a 3 foot long block on a table saw set to five degrees. This is an approximate representation of the trailing edge of the S1223. The ribs make up the majority of the chord, and were accurately cut by a laser cutter. In order to accurately space each rib and ensure each component was straight, a mechanical jig was laser cut for wing assembly. This allowed the team to place each rib in its corresponding section, and glue each rib to the spar, leading edge, and trailing edge. The spar at the first and last rib gap was wrapped in kevlar to reduce the chance of splitting. The aluminum inserts were placed into the spar, the magnets were placed in the outer ribs, and the wings were covered.

Tail Sections

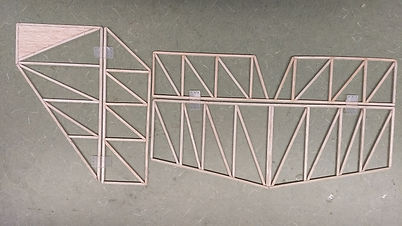

The tail section of the aircraft is made out of 1/8 inch square balsa wood and held together using cyanoacrylate (CA) glue. The framing of the horizontal and vertical stabilizers were modeled after the Pratt truss design. The horizontal stabilizer was permanently attached to the bottom of the fuselage using CA glue. One servo is mounted onto the carbon fiber fuselage to control the elevator. The magnets are secured onto the fuselage and in line with the magnets built into the vertical stabilizer. A wood stiffener helps lock the alignment tubes into place, and makes the lower section of the vertical stabilizer more rigid. The vertical stabilizer also has a servo built into the frame. Two very thin plastic hinges are used to attach the rudder and elevator to the stabilizers. The finished stabilizer is covered using a light heat shrink plastic film.

Payload Mounting Plate

The payload mounting plate is made of a thin carbon fiber sheet. Nylon nuts are centered and glued on the holes to allow for chamfered nylon bolts to be affixed to the mounting plate. Slots of the same dimensions are also cut into the PVC pipe to allow for the nylon bolts to lock into the pipe.

Wing Connector Filler

The Wing Connector Filler is made from a 1x1x6 inch balsa block. The shape of the airfoil was drawn onto the side of the block and then a line was drawn at the base connecting the trailing edge to the leading edge. The shape was then cut out to match the wing panel shape. The base of the block was then cut and sanded to fit over the wing panel connector and the fuselage. The block was then cut on each side at a 12 degree angle to match the angle of the wing panels. Lastly holes were drilled in order to place magnets and carbon fiber rods to prevent the wing panels from sliding.

bottom of page